Benefits of using compound over Masterbatch.

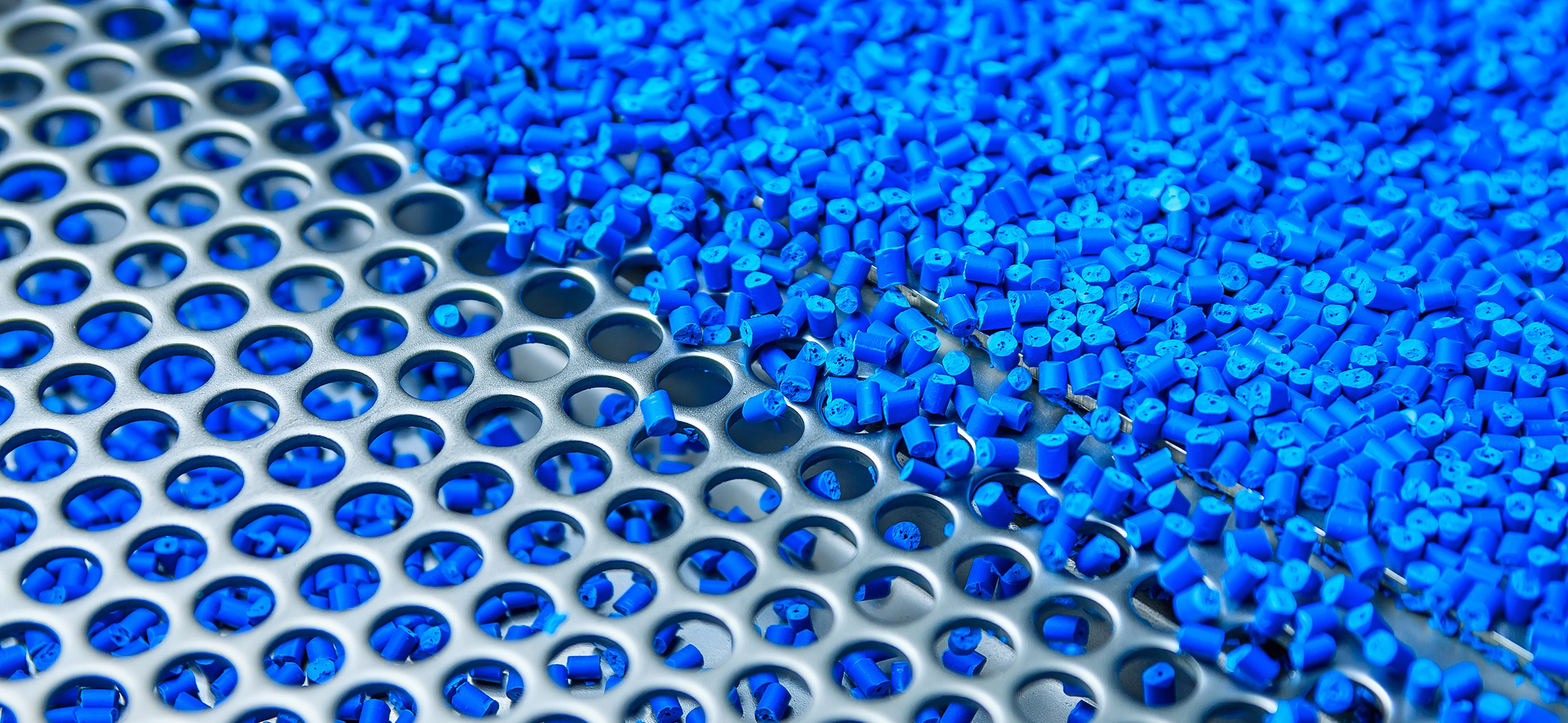

Full compounding is the process of melt blending (blending in a molten state) plastic with colours and/ or additives. This process changes the physical, thermal, electrical or aesthetic properties of the base polymer. The final product is called a compound.

While processes may differ, plastic compounding typically involves a basic set of steps. Additives and colours in the form of pellets, flakes or powders are conveyed through a screw feeder to a container of a molten plastic base material. Blending and dispersal processes ensure that the base material and added ingredients are well combined to create a homogenous final product. The compounded material is then cooled and extruded into pellets, which are then packaged and sold.

This method produces excellent distribution of colour and is very easy to use (no dosing equipment or additional measurements are required). It also provides consistent colour within a batch. Compound Materials are used If you experience inconsistencies when colouring with masterbatch.

PMB compounds can offer you the right solution. We’re able to also run PCR-based compounds to assist customers in meeting sustainability goals and with no minimum order quantity.

Why use compounds.

• Ease of use

• Full colour control and batch to batch consistency sits with us

• Improves consistency in specialist materials that can be difficult to colour